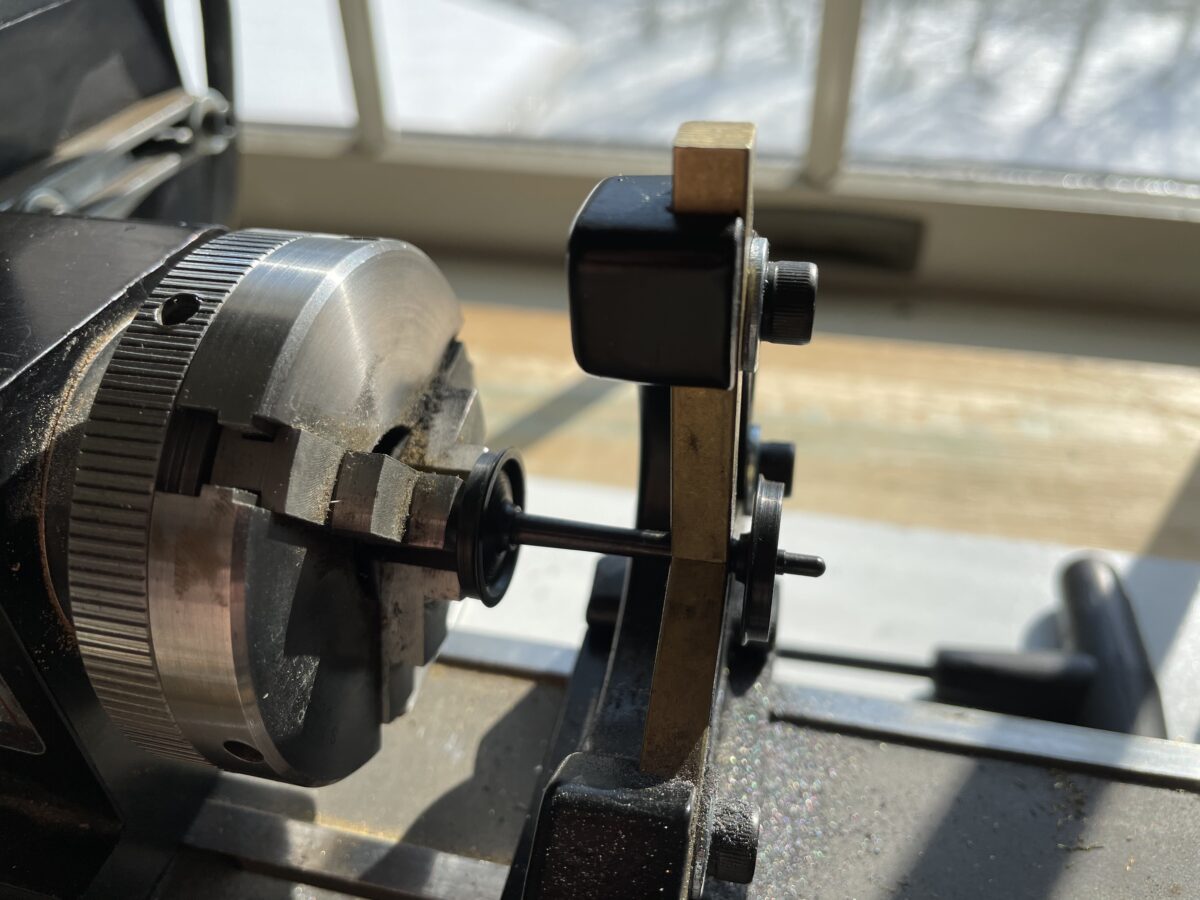

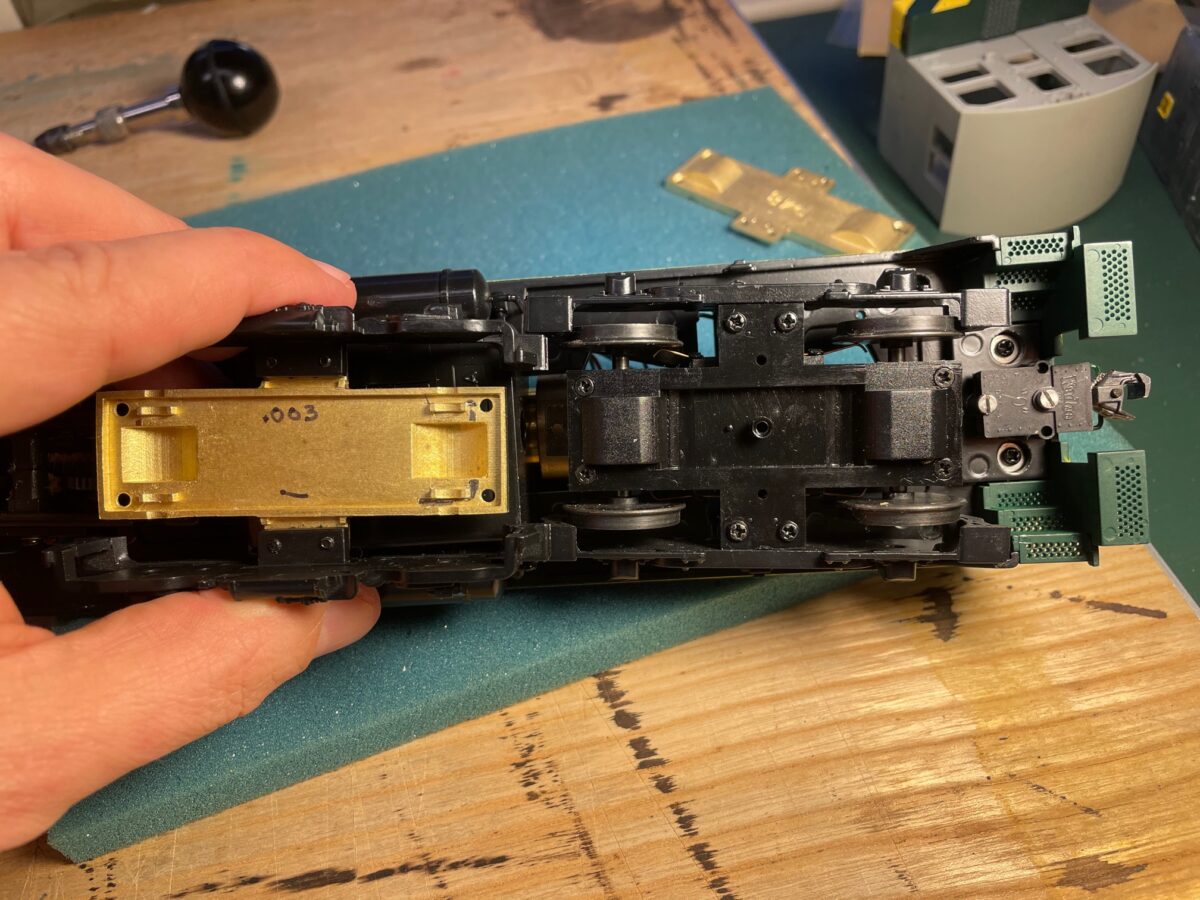

On the workbench this week, two upgrades for an Atlas “O” SW9, the Northwest Short Line P48 wheelsets for an Atlas “O” switcher and the P48 Retainer Plates from Right-O-Way.

I have two Atlas “O” switchers, I thought my one project drive had been converted already. But when I got a phone call from a friend asking about Atlas SW wheelsets, I checked the model and it did have an upgrade set of wheels but they were the .145 NMRA wheels.

No problem, I had a set of P48 wheels on the shelf for a while (check out the old packaging), but the retainer plates I just got in a couple of weeks ago from Right-O-Way.

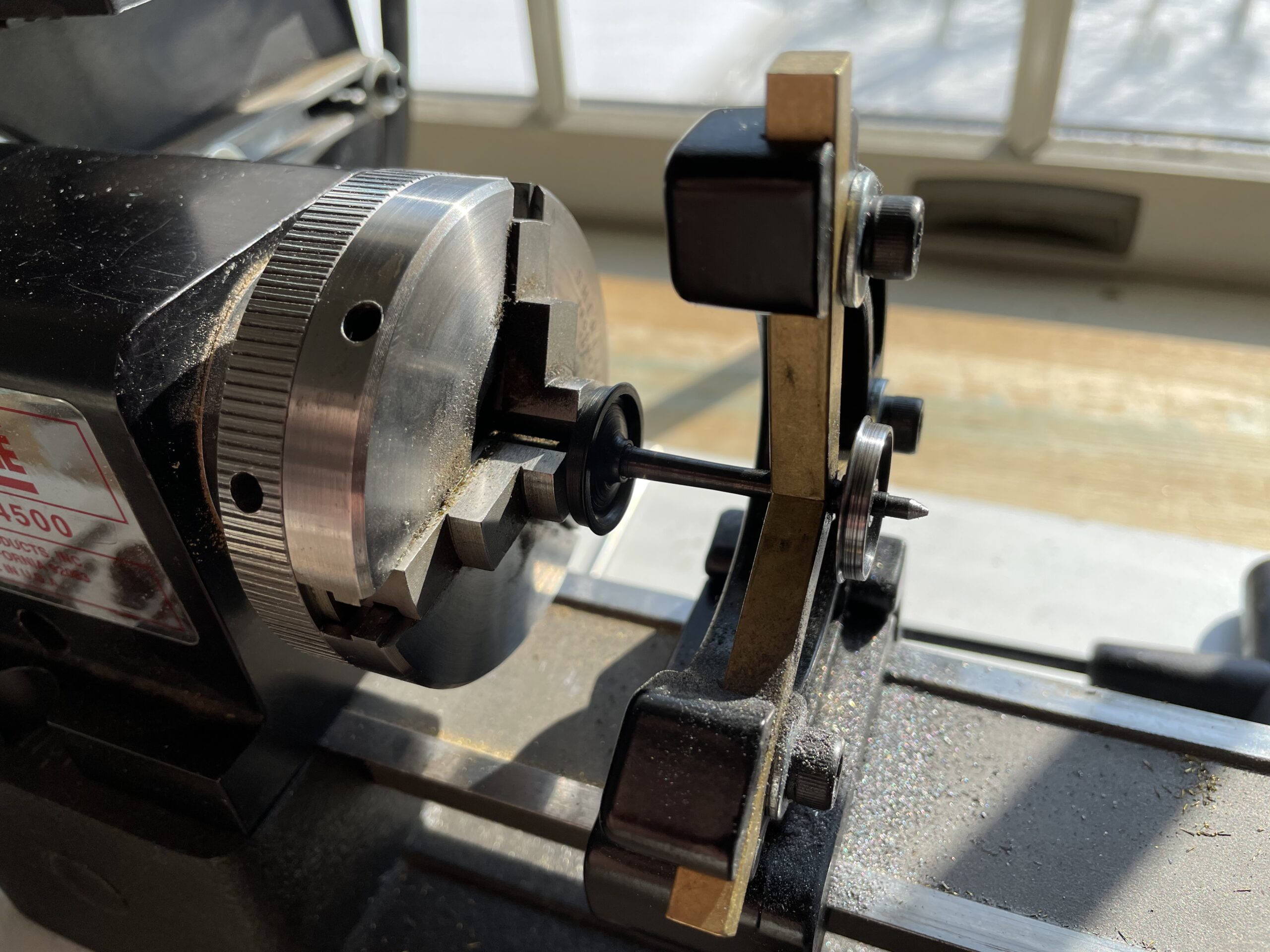

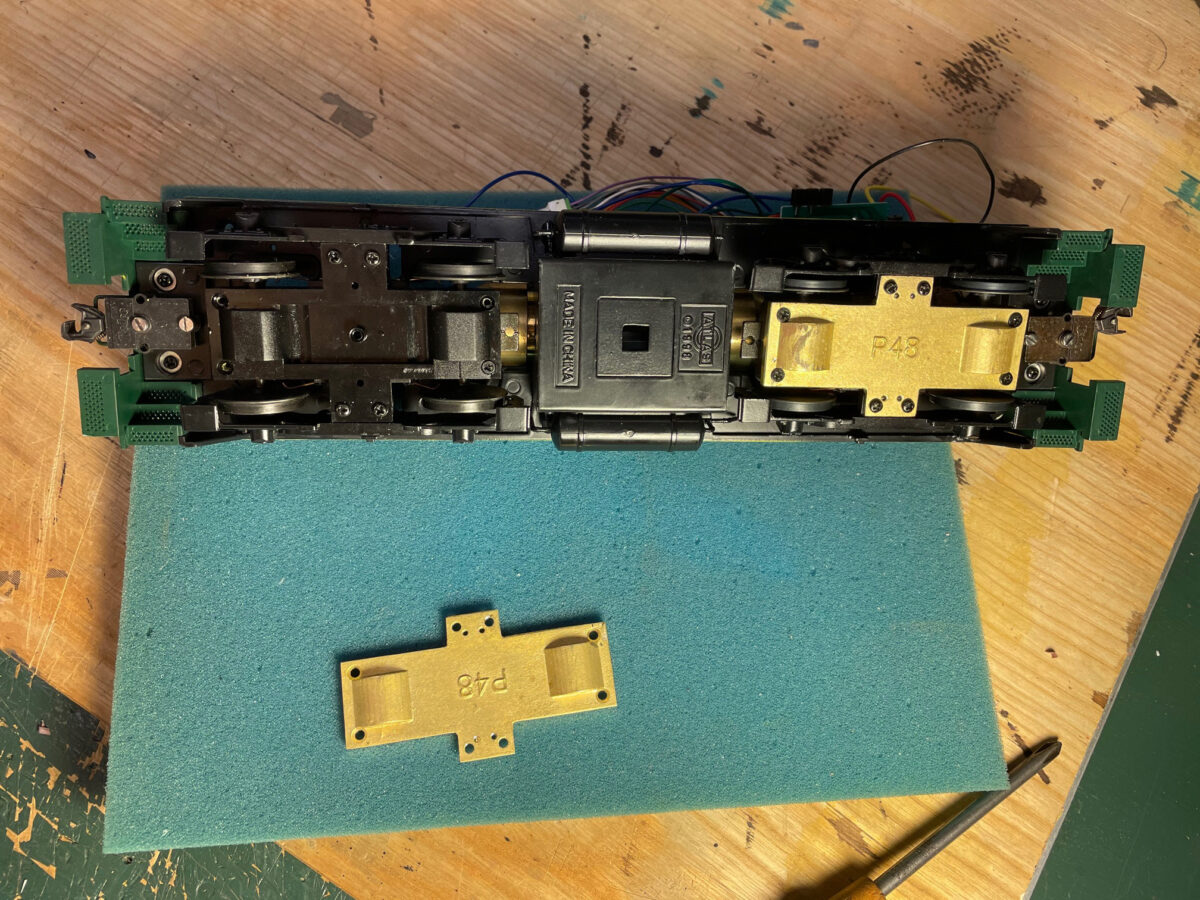

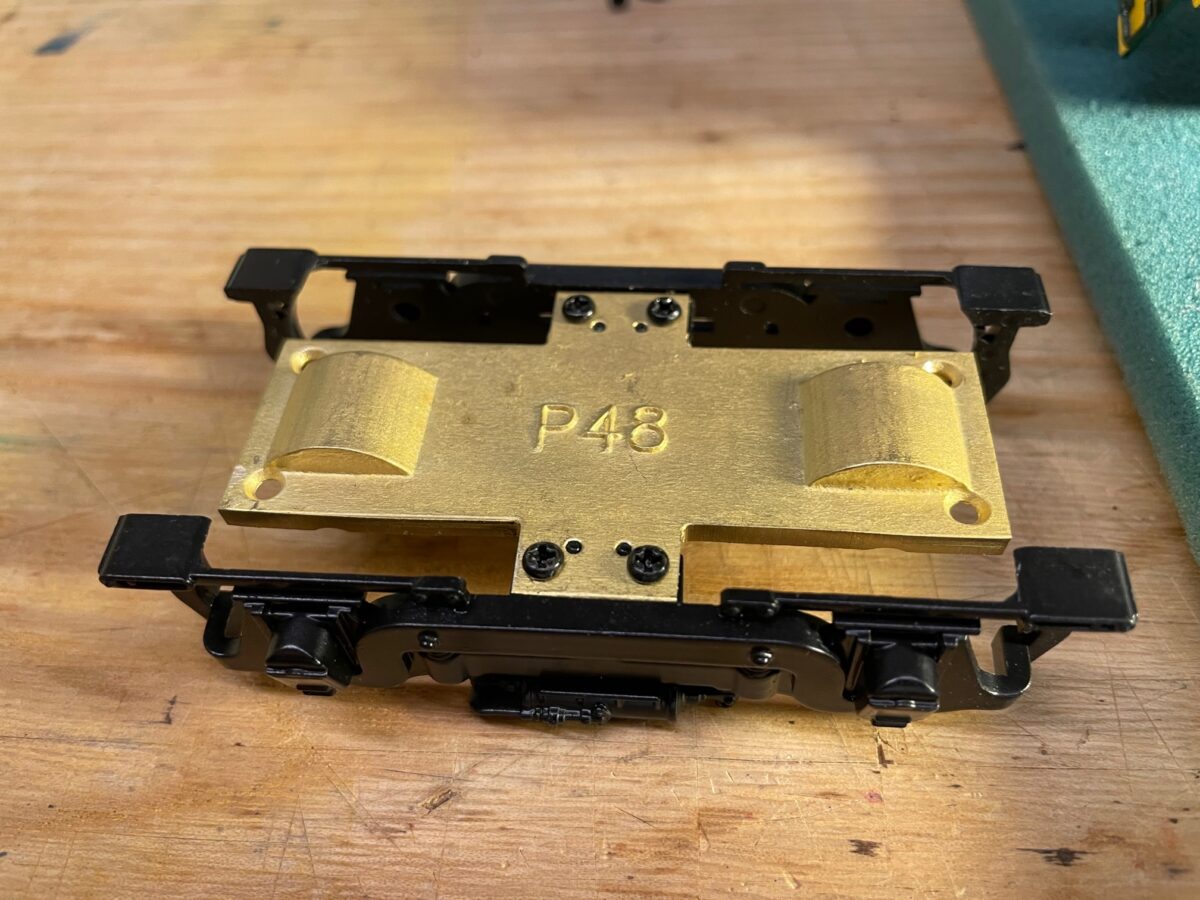

The retainer plate replace the original Atlas part. They are very simple to install, just unscrew the original plate and replace it with the new one.

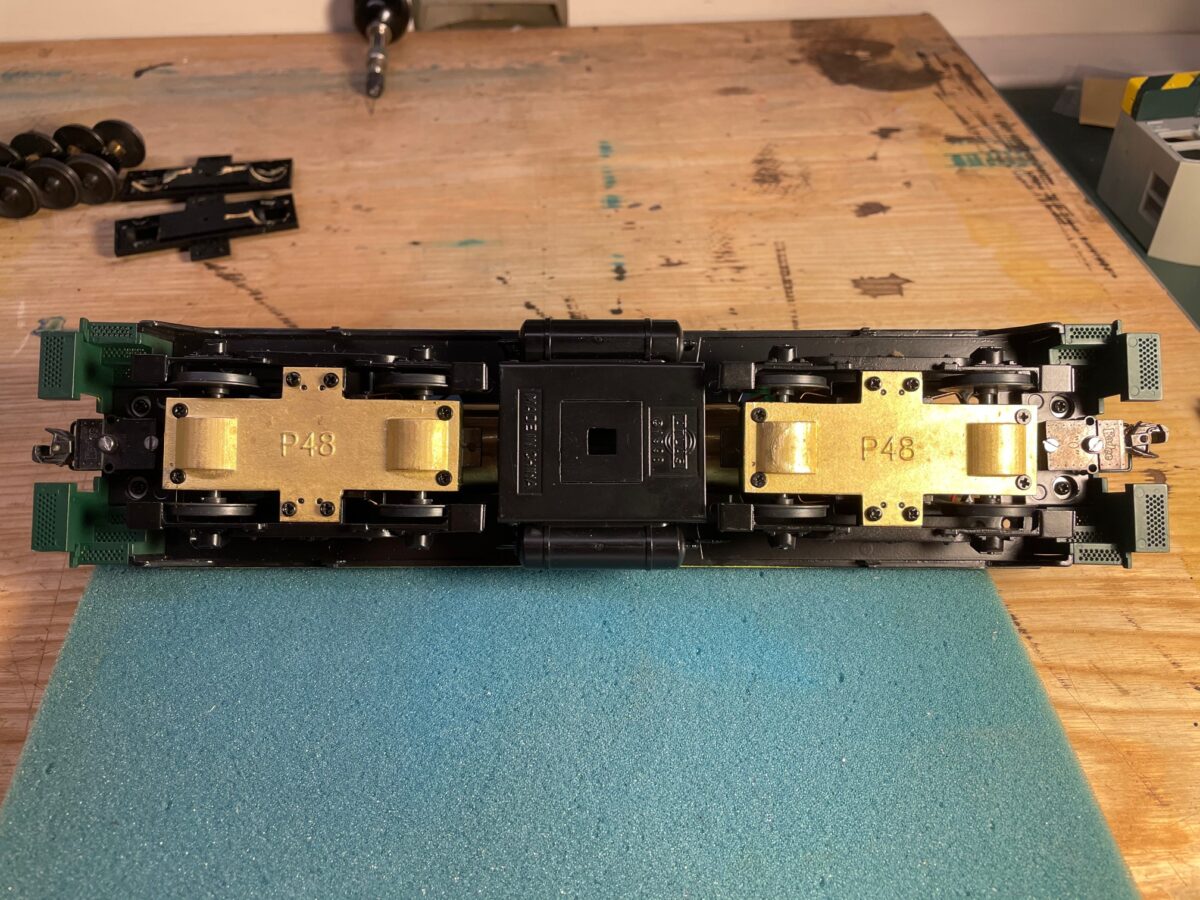

Here you can see how much the ROW retainer Plates pull in the truck side frames. It’s a very simple conversion, four screws remove the retainer plate and four more hold the side frames.

I really should have painted them BEFORE installing them. But my “mistake” allows you to see them more clearly.

All done. My Frankenstein SW9/NW2 project back together. Still not sure this project will continue or be turned back into an SW9.

The Right-O-Way Proto48 Retainer Plates combined with the NWSL Proto48 Conversion Wheelsets really make this a simple and much improved looking conversion. I’ll time it next time, when I do the other switcher. It could not have taken more than a half hour to complete. The only tool required was a Phillips screwdriver.

Right-O-Way sells the retainer plates by themselves or with the conversion wheelsets. They really do make a big difference in the appearence of the trucks.

Right-O-Way website: http://right-o-way.us

Retainer Plates: P48 Retainer Plates

Northwest Short Line website: https://nwsl.com