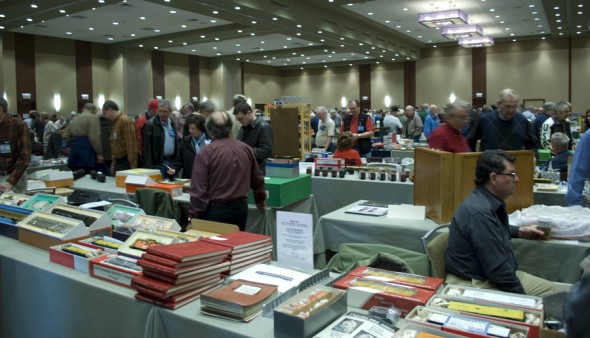

Well for the first time in my life I got to go to the Chicago O Scale Show. I’ve wanted to go for a long time, something always got in the way of my attending the show. This year mother nature tried with 10 inches of snow predicted in Cleveland the night before I was to drive through.

Now this is not just your average show, I was amazed how big it was. It was bigger than most of the Nationals I’ve been to and they do this every year. It did make me wonder why are we stuck with so many small shows here on the East Coast? Why are none of our shows even a third the size of this show?

The selection of models for sale was amazing. I’ll focus on some of the new models I saw at the show.

Ted Schnepf from Rail Unlimited had some new resin kits at the show, of interest to me was the USRA Mill Gondola (Reading GMk and GMl.) One of these kits came home with me so I’ll show you photos of that soon as I start to build it. He also had a new Santa Fe Reefer that looked nice.

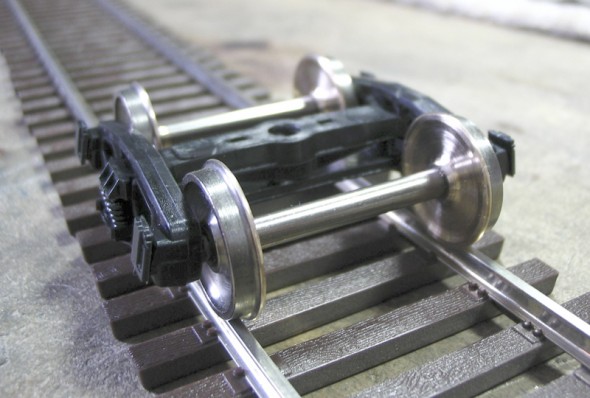

Norm Buckhart of Protocraft was there with some new models. It was nice to finally meet Norm and talk to him about his products. He had a brass sample model of the ACF Reefer he is about to import. He also showed us a Roller Bearing truck that will make the modern guys very happy. Too modern for me, so I didn’t get too excited about it.

Jon Cagle of Southern Car and Foundry had his Harriman cars on display along with his new CP Mini Box. The Mini box is starting to ship I ordered mine at the show. The masters for the car were done by Gene Deimling and the car is great. The major part of the kit is a one piece body plus a roof. I’m looking forward to building the Mini Box and I can’t wait for more freight cars from this new company.

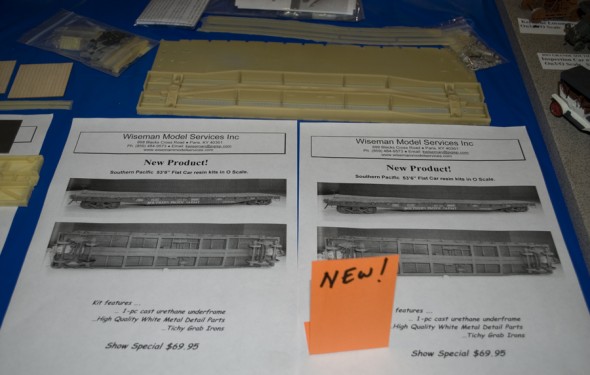

Keith Wiseman also had two new resin cars on his table. One was a Southern prototype and the other was a Southern Pacific car. I was also glad to see he had available the C&O Builders Plates again. I need to order some of their Baldwin Builders plates for my upcoming Baldwin projects.

There were a number of other dealers I got the chance to talk to about parts for projects. Stevenson Preservation Lines was there and I got to pick up a version of the Hodges Trailing Truck that is needed for the K1 Project. We’ll talk about this in depth in a future post here.

Stevenson also had a built up Fox Truck from his castings on display at his table. I know there has been a lot of talk about the importance and need for this truck. Now it seems that three different manufactures have a version for the five modelers across the country that have been lobbing so hard for this truck to be made. With so many other things that are missing in O Scale why?

Middle Division had a resin XL camp car for the PRR on display at Al Small’s table. I’m not sure how these will be sold either through Al as built up cars or as kits. Al Small had one of these in the model contest and took second place in MOW equipment (I think.) I had a chance to see the masters for these cars last Summer at their casters. I was in there to get an idea of the services he offered. HO modelers will note these are cast by the same company that is doing the Baldwin Babyface freighters for ARHS.

Rick Yoder had some new models on display at the table, trouble was they were too popular, as there was always a crowd around the table and I didn’t get a chance to talk much to Rich. I know he was taking orders for his new USRA 70 ton triple and a ACL Watermelon car. I’ll need some of the USRA Triples for my NYC interchange traffic coming from Newberry Junction. Also Rich was taking orders for his PRR 2d-F8 and PRR 2D-F12 trucks.

Glad he was busy though as other Brass importers were signing a gloomy song. It appears that Keystone talking about not doing any more freight car models. They STILL did not have their PRR 2D-F8 truck available. I first saw samples of that truck in 2000, in the basement at Cherry Valley as we were rebuilding the railroad. It doesn’t appear any closer to reality today than it did ten years ago.

Next up I’ll talk about the layout tours.