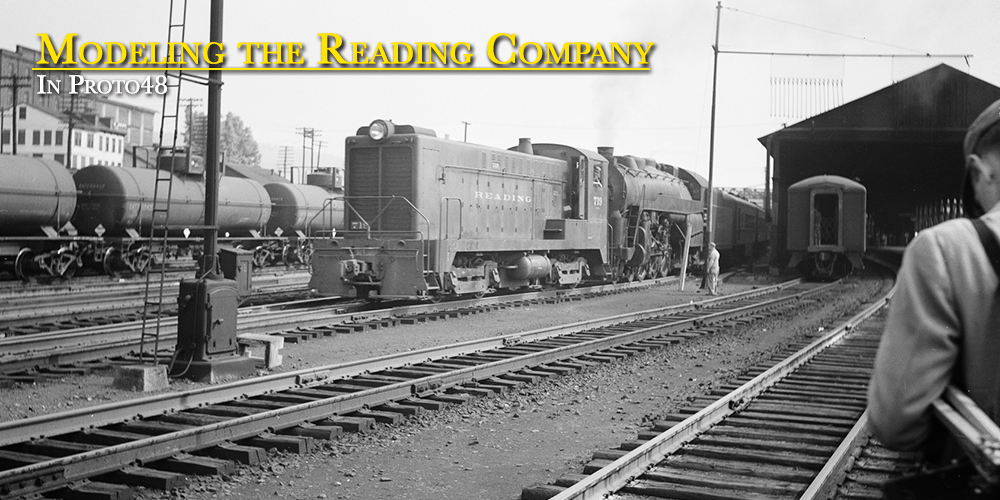

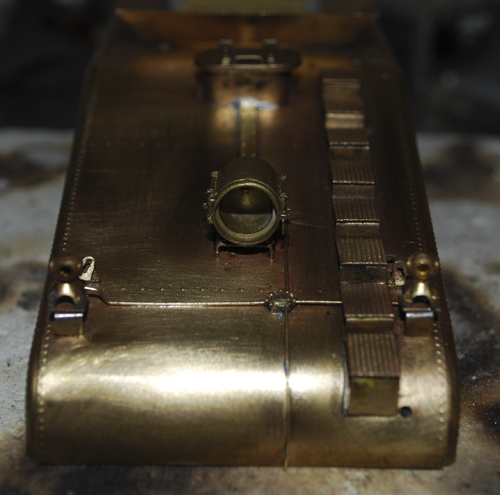

Roy Dietz operating the M1 making setouts.

Roy Dietz’s layout was on the 2009 National tour, I had planned to visit it on the ride North after the National. Just as I was approaching the area to get off of 95 a rather large thunder storm began. I really did not want to follow a bad map in the storm, so I stayed on 95 and figured I’d see the layout some other time.

About three months passed and I was over buying from an estate in Delaware and guess who was also in the basement that night, Roy Dietz. After I was introduced, I told him the story about not getting to see the layout because of the storm. He was nice enough to invite me over. But he said rather than just, see the layout like you would have after the National, why not come over and operate the layout?

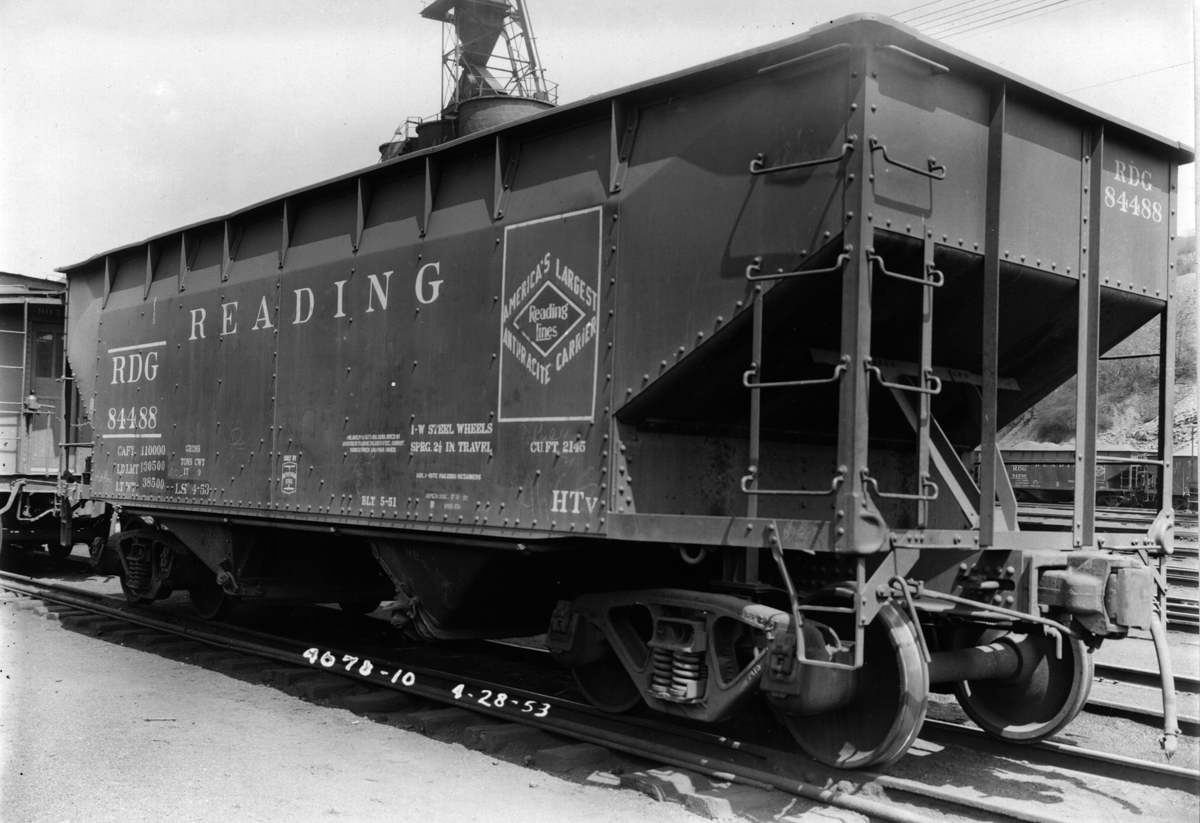

I tried to round up a few folks to go with me but only one brave sole that day Matt Forsyth. We drove down to Maryland and found the home that housed the railroad. Roy had moved into the house just a couple of years before and built this new railroad. As you descend into the room the first scene you are confronted with is Harrisburg Passenger station. He has modeled the exchange of power at Harrisburg, which is the furthest point West that the electrics worked on the PRR. There is also a couple of smaller rural towns modeled which allow for the bulk of the freight operations.

Yes, I did say operations. We operated a PRR RS-3 switcher pulling cars out of sidings placing car out for interchange and setting new cars back into the industries. I have to say that afternoon moved me. I had more fun with a simple switcher shifting cars around then I ever did while a member of a club. Trains are not meant to run in circles they are meant to deliver goods to and from industries.

This has caused me to rethink a lot of what I was planning.

Setouts dropped, now picking up cars.

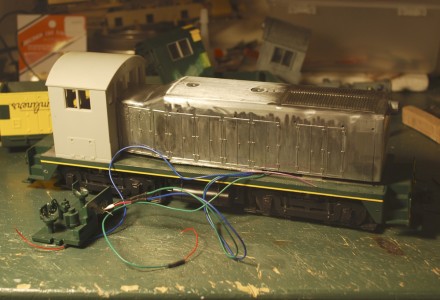

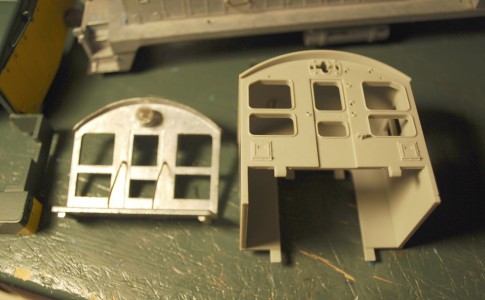

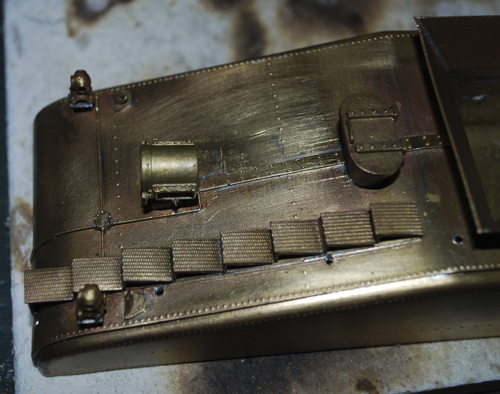

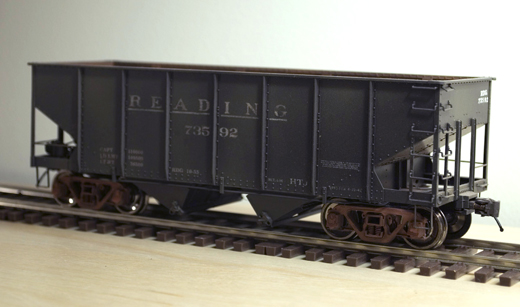

The Simple Weaver Switcher that caused all the FUN!

Another industry to switch. the other side of the industries

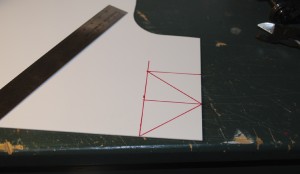

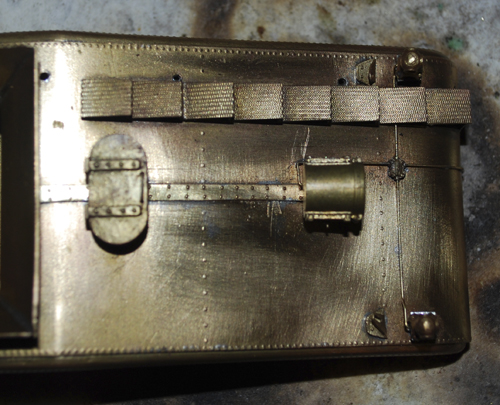

Roy’s switch point design.

A GG1 brings a passenger train into Harrisburg

Roy cuts off the GG1 and moves it out of position

A pair of E7a’s move to couple up to the train.

The E7’s take the train West.

The train headed west