“Drop-In Conversion Parts” that is such a nice phrase. It’s not always a reality.

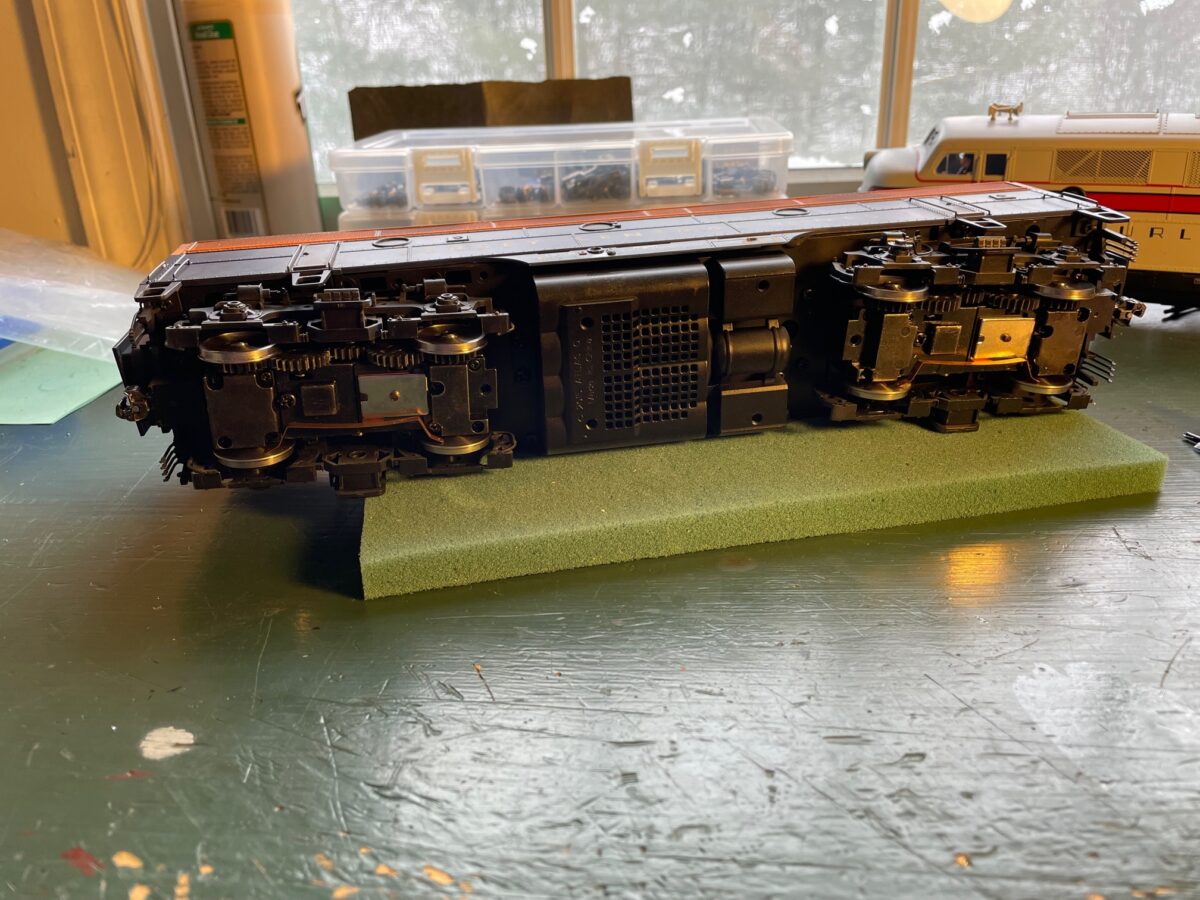

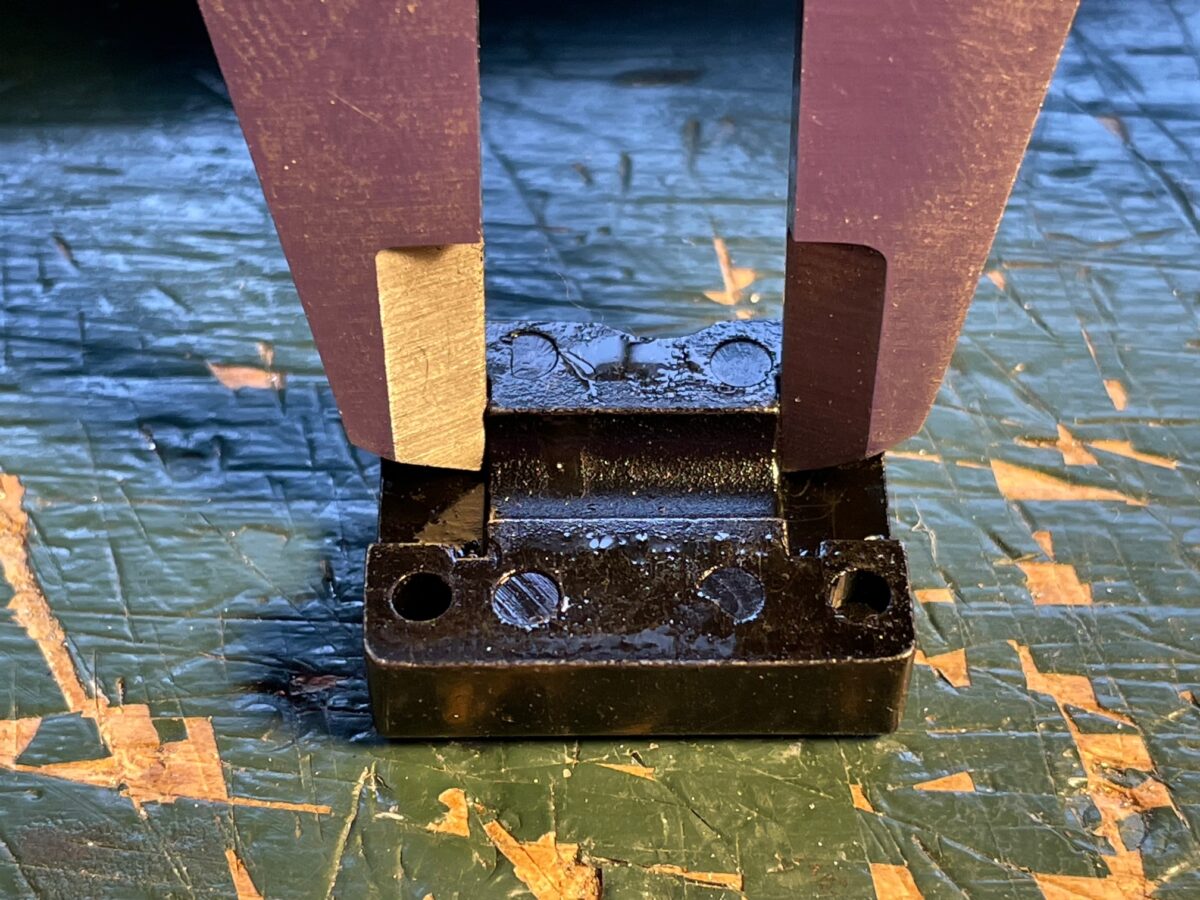

If you read yesterday’s post you know of my troubles installing the NWSL conversion wheelsets into the Atlas O F3B. To recap the back to back of the ridge on the bushings needed to be at least 0.496″.

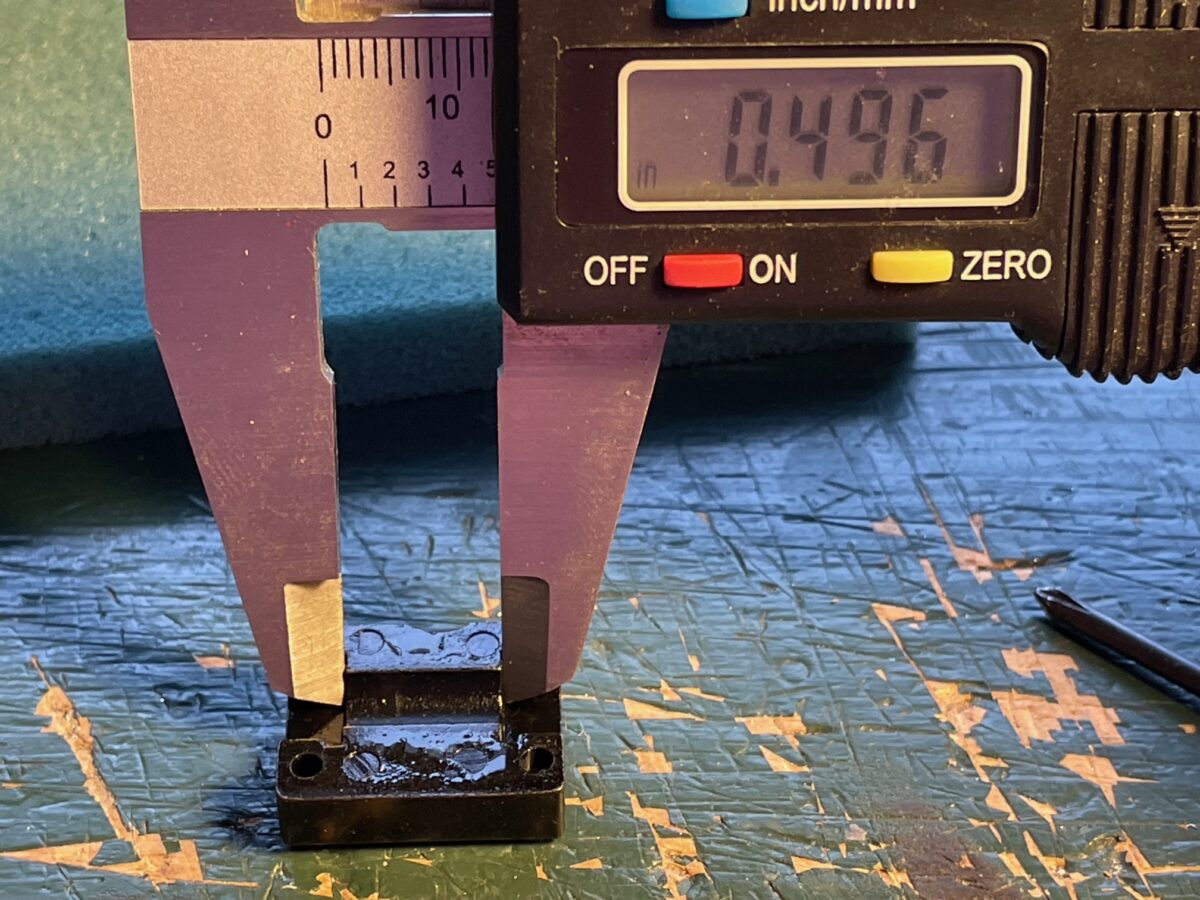

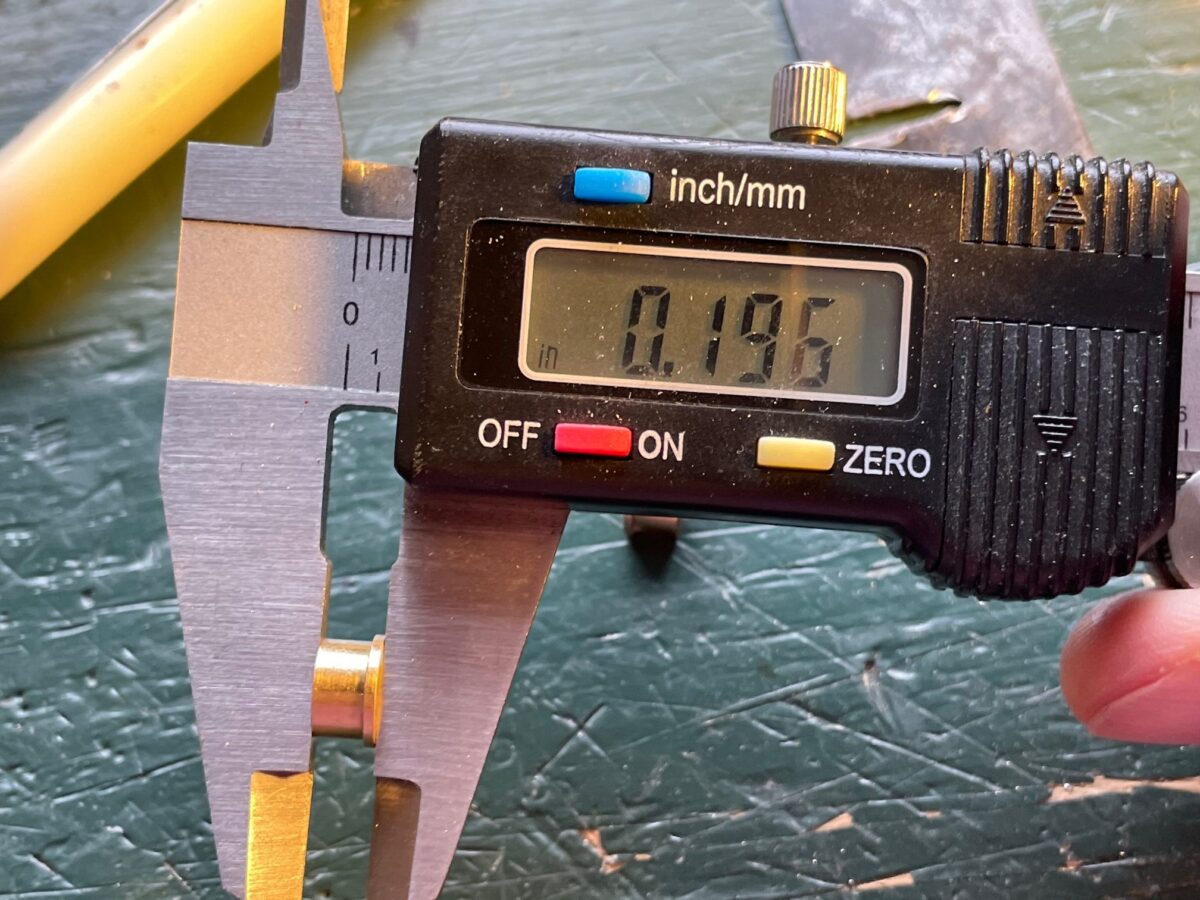

The NWSL parts had a back to back measurement of 0.488″ – 0.490″.

I know it’s only 0.006″ – 0.008″ difference but that is the difference of them fitting or not.

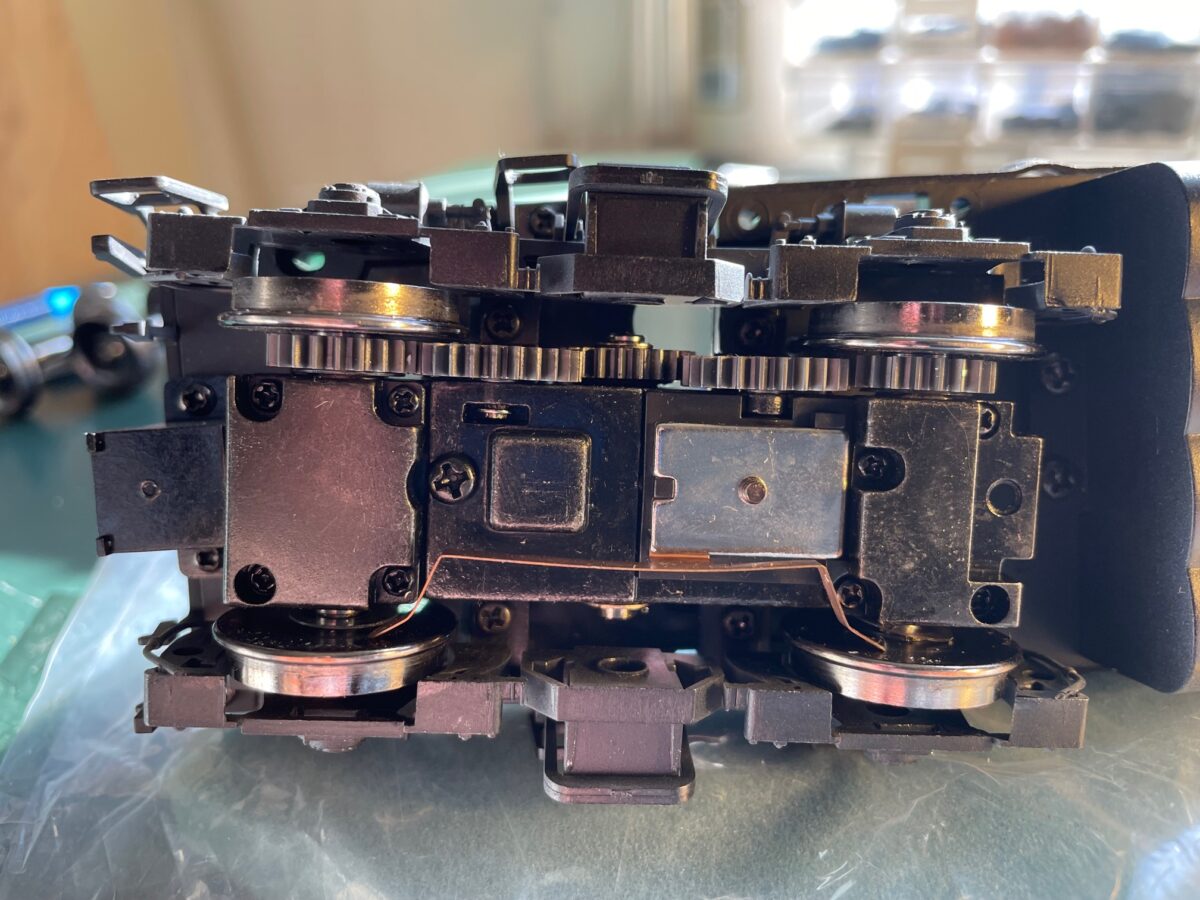

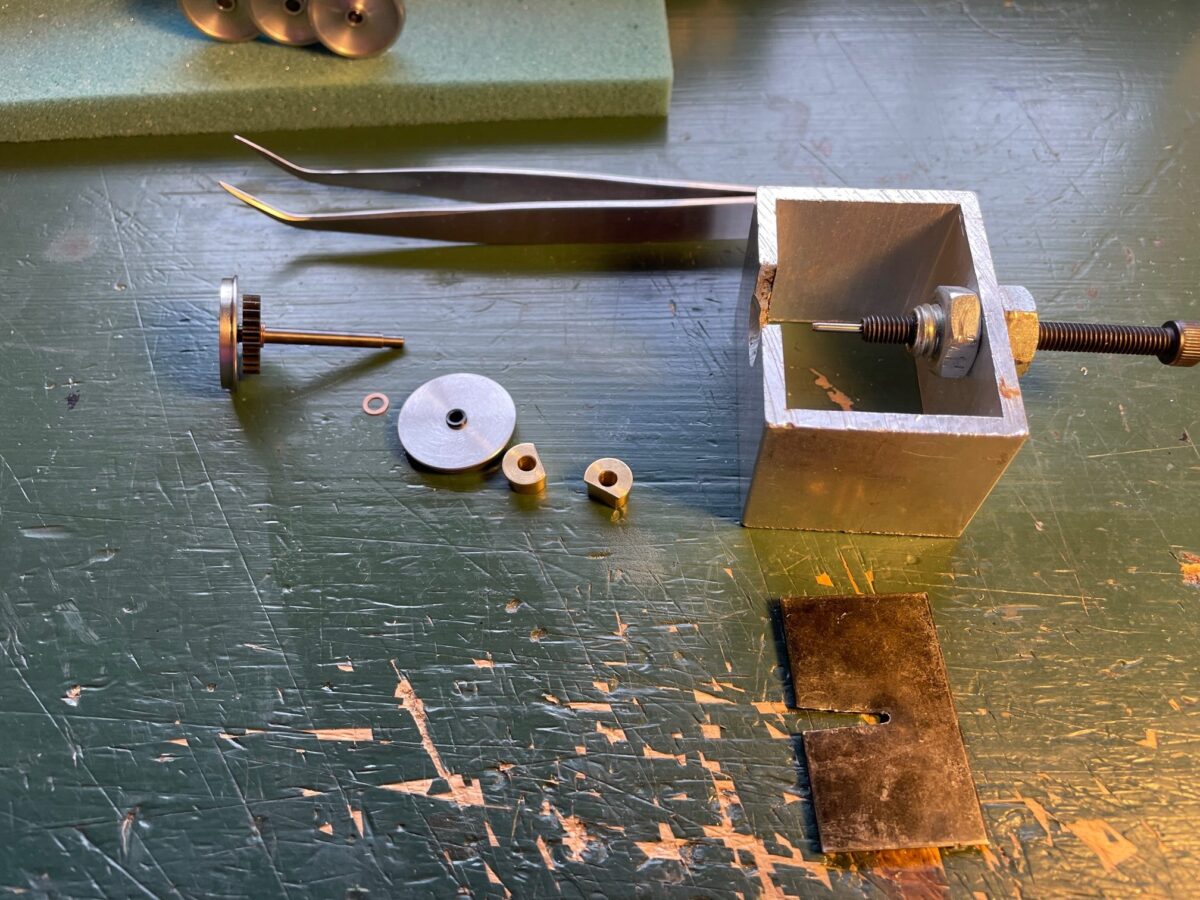

Time to disassemble the first axel.

This was the before measurement for the bushing.

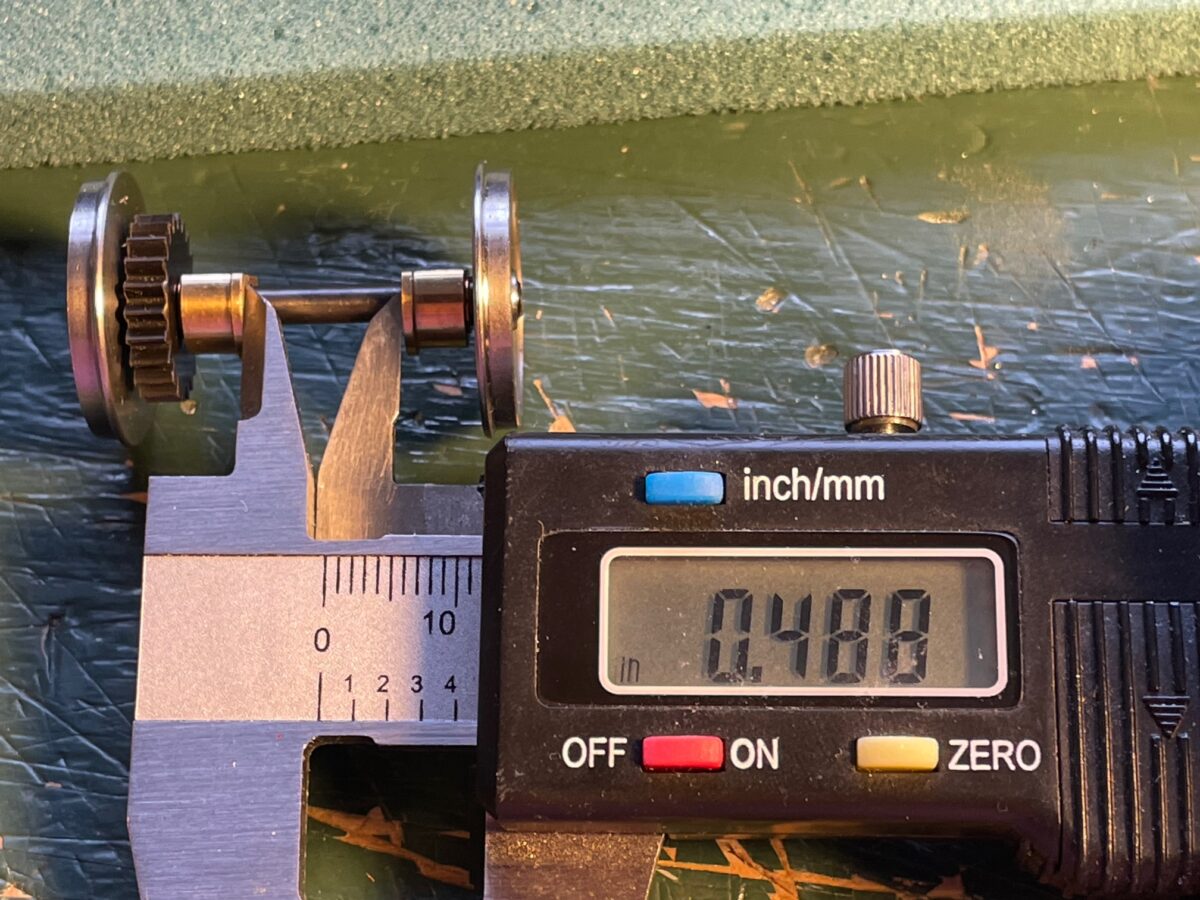

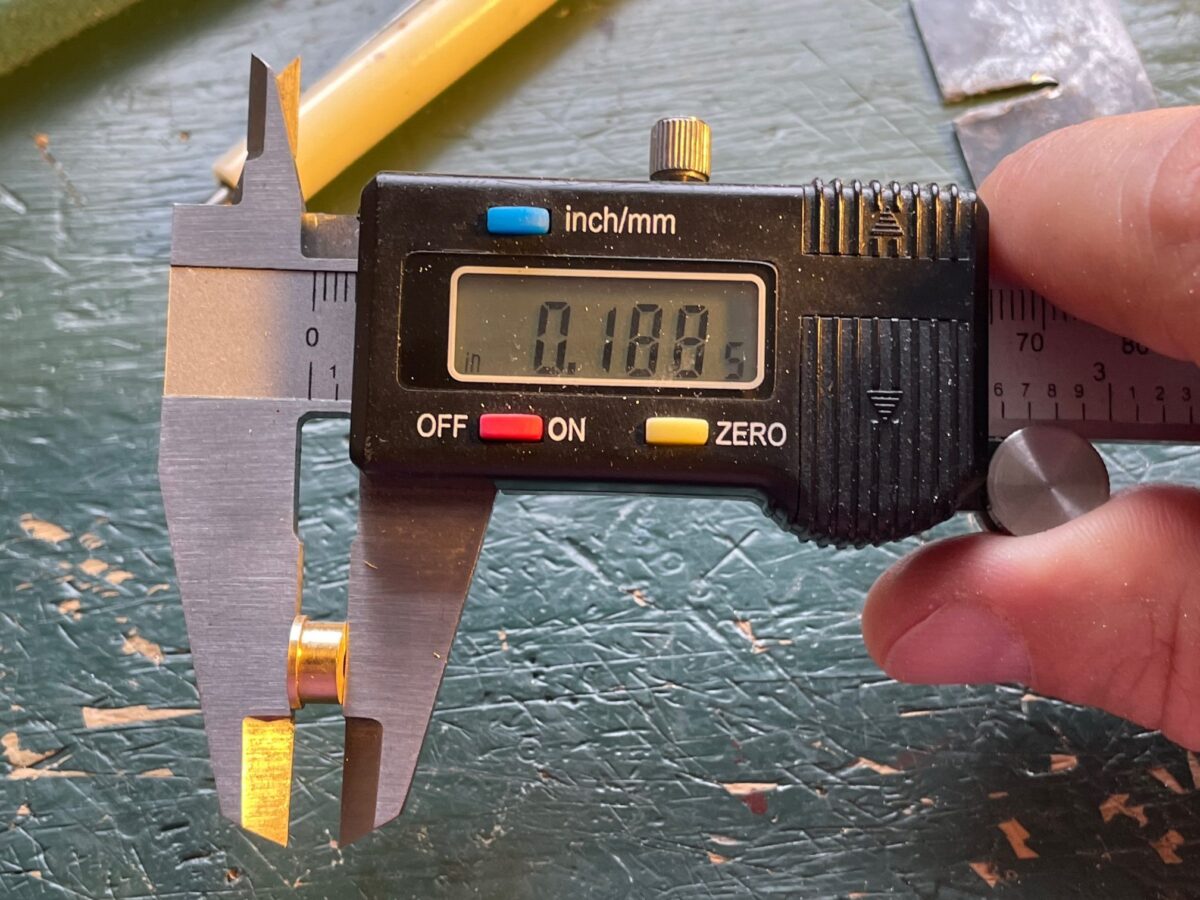

This is the bushing’s measurement after it went on a diet.

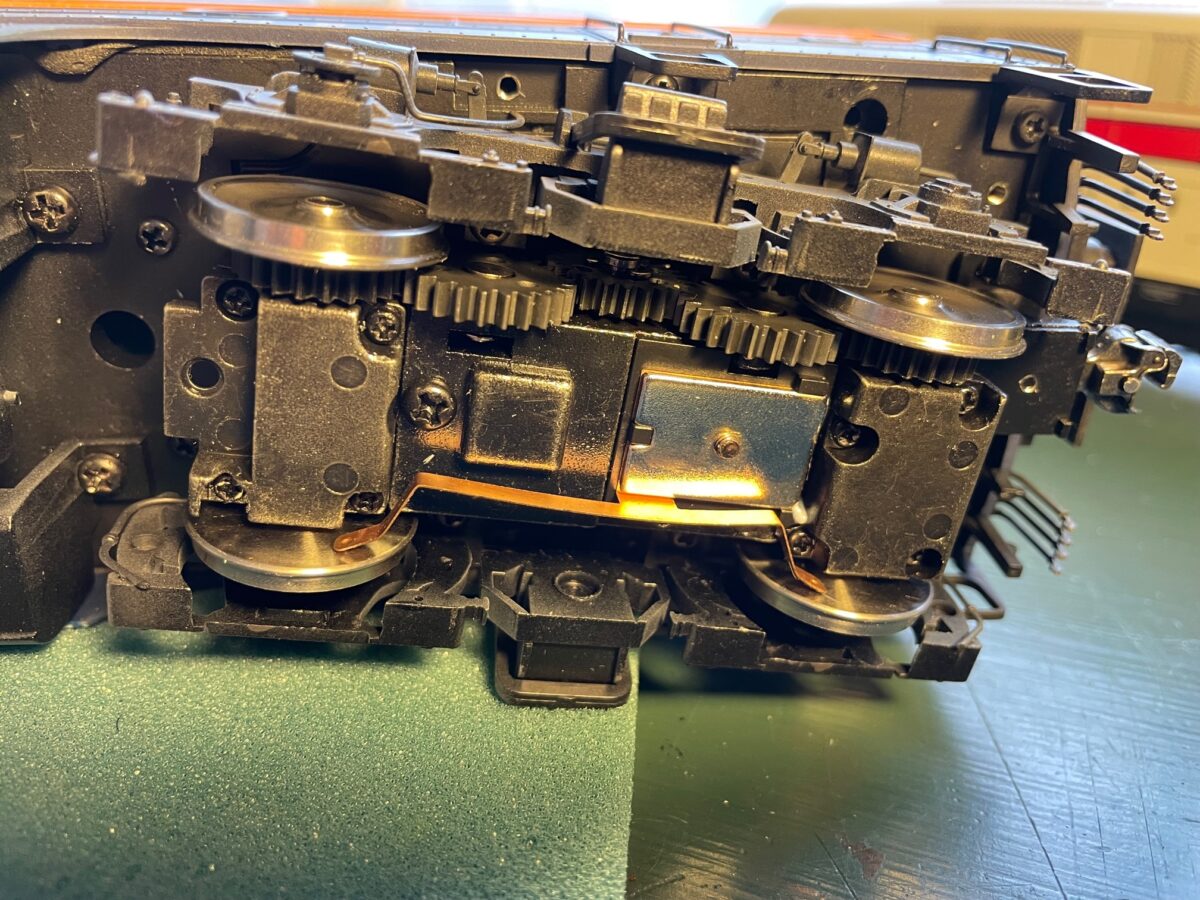

The new back to back measurement. And the most important thing….. They ACTUALLY were a drop-in fit into the grove on the top cover.

After modifying the two axels that didn’t fit, I had to open up the one truck where the axels did fit. I knew they were a very tight fit and just thought they would benefit from also being modified in the same manor.

I am happy to report that this last photo shows all four axels modified and installed. Next time I work on this model, those side frames need to move a lot closer to the wheels, but that is work for another day.

Truth be told, it took about the same amount of time to write this post as it did modify the bushings to make the axels fit properly. So it really wasn’t a big deal at all.

I’m still bothered that the conversion parts did not fit as delivered from NWSL. I’ve been modeling in Proto48 since the early ’90’s, I know there is no instant gratification in Proto48. We have to actually work on our models.

What if I was a newcomer to Proto48, this experience would have been very discouraging. It could have easily made me question if modeling in Proto48 was worth the extra effort. Sometimes the newcomer to Proto48 needs some simple wins to give them the motivation to keep going and try more difficult projects. This type of Proto48 conversion should be one of those simple wins.

Thankfully, the remedy was painless.